EVMU in Airbus A320 – Monitoring the Heartbeat of Your Engines

️When it comes to keeping our engines running smoothly, monitoring vibration is key to safety, performance, and maintenance planning 🔍🛠️

That’s where the Engine Vibration Monitoring Unit (EVMU) steps in — a smart, silent guardian of your CFM56 or V2500 engines onboard the Airbus A320. 🧠🌡️

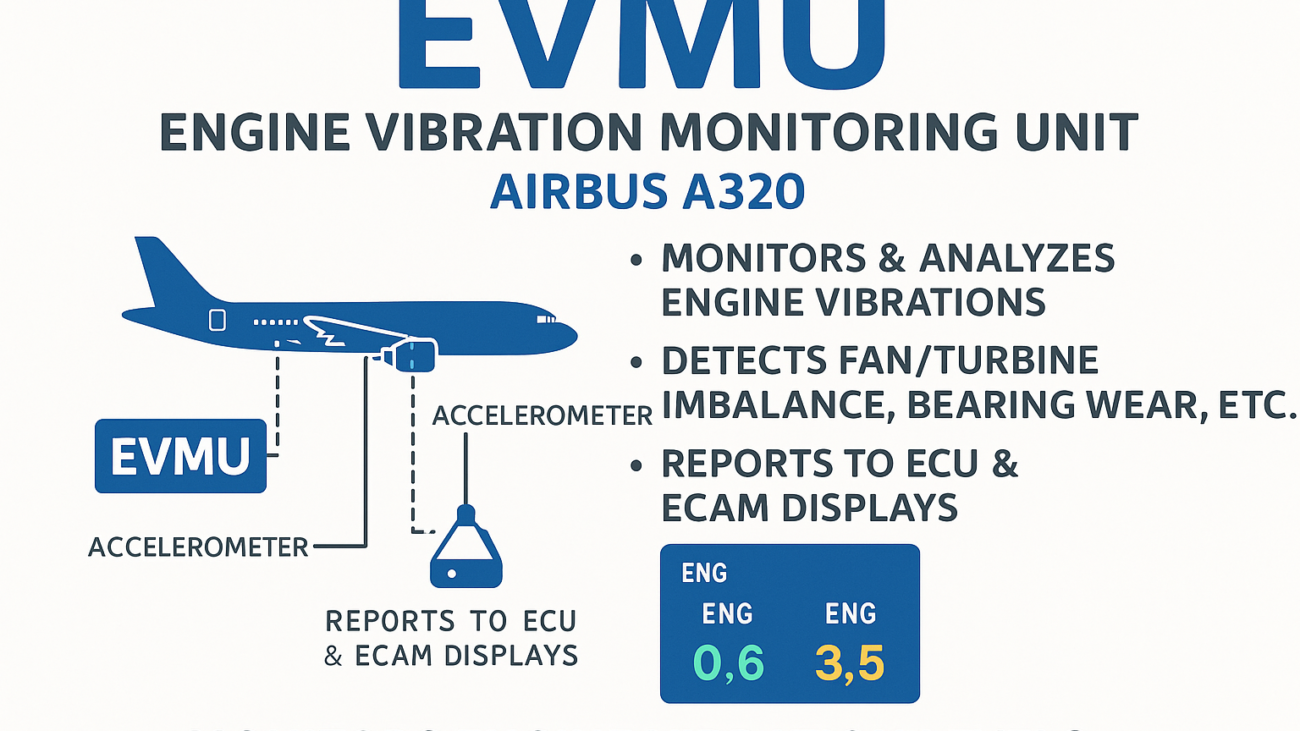

What is the EVMU?

The EVMU continuously monitors and analyzes engine vibrations — helping detect:

⚠️ Imbalance in fan or turbine modules

🔧 Bearing wear or looseness

📉 Structural resonance or abnormal loads

It measures vibration using accelerometers mounted on each engine (typically near the fan or LP turbine), then sends data to the ECU (Engine Control Unit) and ECAM displays for flight crew awareness.

EVMU Data on ECAM:

👨✈️ On the Airbus A320 ECAM system, you can view vibration levels per engine (ENG 1 / ENG 2):

Green = Normal ✳️

Amber = Caution ❗

Red = Excessive 🔥

Pilots can use this info to adjust thrust, report to maintenance, or log for trend monitoring.

For Maintenance & Engineers:

The EVMU is a powerful diagnostic tool 📈

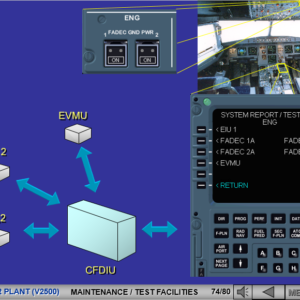

Using post-flight reports or CFDS via MCDU, maintenance engineers can:

Detect early signs of mechanical damage

Plan engine balancing or borescope inspections

Prevent expensive unscheduled removals 💰⏱️

Why Does It Matter?

✅ Improves safety

✅ Reduces maintenance cost

✅ Extends engine life

✅ Enhances predictive maintenance (MSG-3 aligned)

🎥 Learn More:

Want a detailed understanding of engine vibration monitoring logic?

Watch this short but helpful video:

🎥 Discover how the Aircraft Engine Vibration Detection System works through this clear and engaging video demonstration:

🔗 https://lnkd.in/dcMvY7Cd

💬 Have you ever encountered an in-flight vibration warning?

Drop a comment — I’d love to hear your experience from the cockpit or the hangar floor.

#AirbusA320 #EVMU #EngineVibration #Avionics #MaintenanceEngineering hashtag#CFM56 hashtag#V2500 #AerospaceEngineering #FlightSafety #TechnicalTraining #LinkedInAviation